Laboratory glassware is a ubiquitous aspect of chemistry. In fact, it practically predates the field. Alchemists of the 17th Century were using crystal glass flasks and vessels before chemistry was fully realised. During this period, a new class of budding researchers dedicated themselves to simulating natural phenomena in laboratory conditions to answer some of the most pressing questions of the age. This was the proto-scientific field of “chymistry”. High quality glass was favoured by these pioneers for its transparency and chemical resistance – qualities that are just as relevant today.

Modern scientific glassware is naturally more sophisticated than the vessels used two hundred years ago. Chemists utilise borosilicate glass and complex flow chemistry setups to achieve optimal reactions in situ. However, configuring the right chemistry setup can sometimes feel even more elusive than alchemy!

This article serves as your quick guide to laboratory glass joints and fitting sizes – an area of knowledge for scientific glassware that’s essential if your setup is to work as intended. If you still have questions by the end of the blog, please don’t hesitate to contact us directly.

What is a Ground Glass Joint?

A ground glass joint is the basic connection between two pieces of laboratory glassware. It is called a “ground” joint simply because the mating surfaces are polished to an extremely smooth finish, thus ensuring the best possible fit. Modern glass joints are typically finished to such a degree that apparatus can be easily fitted together in a leak-tight setup.

Various joint types exist, but the most commonplace are the ball-and-socket and standard taper. Many others (i.e. the lower joint size and cone joint) can be considered variations of these two main configurations, given that they use either a basic conical shape or a ball-shaped end that slots into a socket. Choosing the right glass joint generally depends on your existing glassware and requirements. For example: If you are using a bottom flask in a distillation setup, you might pair it with a standard taper or cone on a condenser; while you may use a socket joint on a heating mantle in a thermal experiment.

Another important facet of each joint type is that they follow standardised dimensions. We’ll discuss those in the next section.

What are the Joint Sizes of Chemistry Glassware?

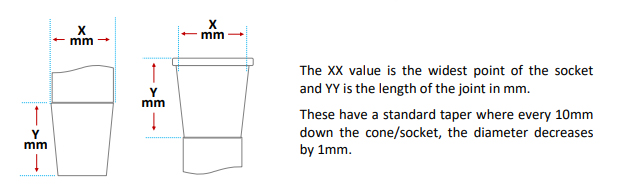

Fitting sizes refer to the standard measurements used to ensure that your glassware joints fit together properly. Each joint is sized by its length and width and is typically expressed as two, two-digit numbers (i.e. XX/YY). In this expression, XX is the width of the socket’s widest point, and YY is the length of the joint. The diameter should decrease by a factor of 10:1 down the length.

It is important to note that although glass joint sizes are standardized they do differ from region to region. The difference is highlighted by regional “nicknames”. For instance: European standard tapers are often called B joints. These are manufactured for compliance with ISO 383:1976; which specifies the conicity, great diameter, and length. Sometimes B joints are called NS (NormalSchliff) joints, though this refers to the German standard DIN 12 242. It is more common to find European cone joints nicknamed for their width, so a B14 is a cone joint with an outer diameter (OD) of 14mm. A B19 has an OD of 19 mm, and so on.

B joints are generally smaller than counterparts used in other parts of the world, including the USA. This can cause compatibility issues. Just as in Europe, America has two derivations of cone or standard taper: the A and the TS joint. Just as the European joint is named after a standard, the A joint gets its name from the ASTM classification system.

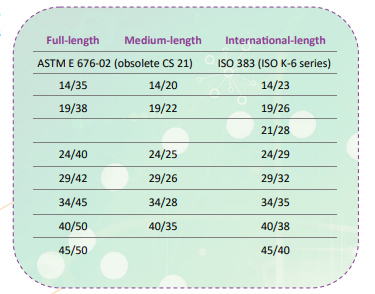

Within these two categories are three different lengths: full-, medium- and international-length. A B14 and international-length A14 are equivalent in OD and length, while a mid-length A14 is shorter at 20mm, and the full-length is longer at 35mm. It is easy to see how this could quickly cause compatibility issues if mistakes are made!

Looking for More Information?

At Asynt, we pride ourselves on offering a broad range of scientific glassware to suit various setups. This demands a certain level of expertise in configuration. We have an expert team of scientific glassblowers and chemists with real-world experience in the lab at our disposal, and we are happy to answer any lingering questions you may have about fitting laboratory glassware together. You may wish to download our flyer which contains an overview of common sizes and how to discern them from each other HERE.

Contact us today. We are confident that we will meet your needs and exceed your expectations, whether you are searching for the elixir of life or performing more standard wet chemistry techniques.

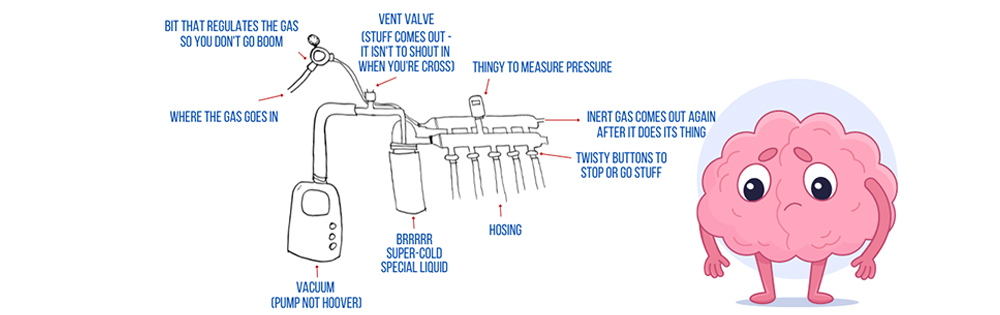

If you’d like to carry on reading, perhaps our recent blog with a guide to Schlenk Lines will interest you? This includes a summary of the system, and useful assistance from the Schlenk Line Survival Guide.