Solvent evaporators are essential laboratory instruments that evaporate solvents or water from a sample. They are widely used in the pharmaceutical, environmental, and food and beverage industries to prepare samples for further analysis. In science, solvent evaporators find applications in chromatography, drug discovery, and material synthesis preparation methods. This blog post provides a technical overview of solvent evaporators, their types, and their use with tubes and vials.

Types of Solvent Evaporators

Solvent evaporators come in various configurations, each with its own advantages. The different types available include heat, nitrogen, rotary, centrifugal, and vacuum evaporators. These evaporators use gas, heat, motion, reduced pressure, or multiple methods to speed up evaporation. Let’s take a look at three common solvent evaporators:

- Rotary evaporator: A rotary evaporator uses a combination of heat, rotation, and vacuum to rotate a vial in a heated water bath for evaporation. Rotary evaporation is an ideal solution for processes that must be carefully controlled.

- Centrifugal evaporator: A centrifugal evaporator uses a centrifuge chamber, solvent condenser, and vacuum pump and is most suitable for when different liquids must be evaporated at low temperatures.

- Tube evaporator: Tube evaporation is another option for solvents with high boiling points, as evaporating solvents via parallel tubes removes the need for high-temperature sources.

Considerations When Choosing a Solvent Evaporator

When choosing a solvent evaporator, it is important to consider specific features such as the size and type of sample used, speed of evaporation, solvent recovery system if the process requires tubes and vials, and the maximum boiling point the evaporator can handle. It is also worth noting that conventional evaporation equipment can represent an enormous expense.

Using Tubes and Vials with Solvent Evaporators

Tubes and vials are essential to ensure solvents are evaporated efficiently and reduce the risk of sample contamination. They allow rapid evaporation, and enable different samples to evaporate simultaneously. Depending on the type of evaporator, tubes and vials of various shapes and sizes can be loaded onto it to support efficient and safe evaporation. Some evaporator models enable height adjustment and larger tube holdings to suit specific applications.

The tubes come in different shapes and sizes, can be manufactured from several different materials, such as glass or plastic, and are used for processing, storing and transporting samples. In terms of solvent evaporation, tubes and vials are essential to ensure solvents are evaporated efficiently and reduce the risk of sample contamination. As mentioned above, tube evaporators are useful when solvents with high boiling points must be removed without being heated to high temperatures. Typically, the high boiling solvents are water, DMSO and DMF.

Asynt: Tubes and Vials for Solvent Evaporators

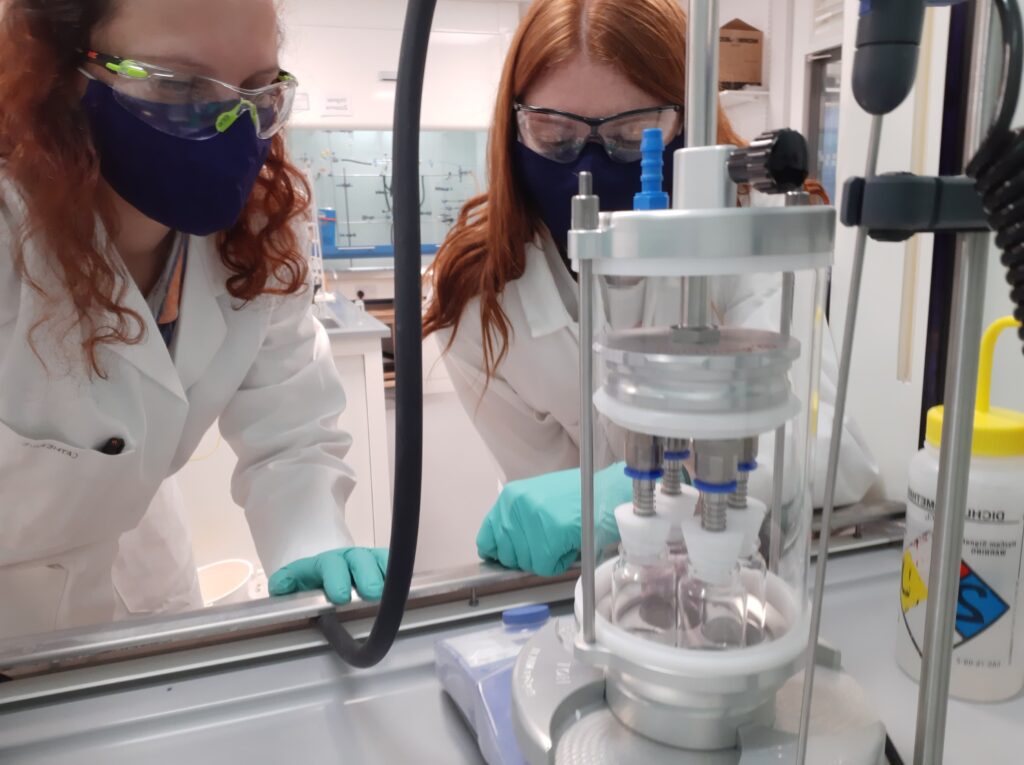

Ready to take your solvent evaporation process to the next level? Check out our DrySyn Spiral Evaporator, specifically designed for parallel evaporation in tubes or vials, even for high-boiling solvents like water, DMSO, and DMF. With its unique design to prevent solvent bumping and enable fast and effective evaporation, the DrySyn Spiral Evaporator is the perfect addition to your laboratory. Contact us today to learn more about this innovative product and how it can help optimize your research workflow.

Further Reading: Colloidal Nanoparticles Advance Frontiers of Synthetic Chemistry

Further Reading: Colloidal Nanoparticles Advance Frontiers of Synthetic Chemistry

New solutions to old problems

At Asynt, we take pride in offering a wide range of solutions for laboratory applications. But we also believe in the power of customization. We encourage scientists to always strive for their specific needs and to reach out to us for customized solutions if they need help finding what they’re looking for in our standard offerings. We’re here to help you achieve your research goals as effectively and efficiently as possible. The DrySyn Spiral Evaporator, mentioned above, is a direct result of our R&D team expanding upon existing solutions to design a tool that is more accessible, and just as effective, as those big-spend options.

BESPOKE DESIGN & ENGINEERING

|

|

|

|