Photochemistry is an important discipline concerned with the chemical processes induced by light absorption. The applications of photochemical processes are myriad, ranging from air and water purification to surface disinfection, and the central tool in each of these is the photoreactor. A photoreactor is a unique light source used to safely induce or accelerate chemical reactions. Their applicability and performance vary, especially depending on the wavelength of interest. Given its high energy and extremely short wavebands, ultrasound (UV) is routinely used in photochemical processes. Yet there is enormous variability between different UV photoreactors, with performance differing based on the type of light source and control system. In this blog post, we will look at more of these critical features in detail and how each impacts a UV photoreactor.

UV Light Source

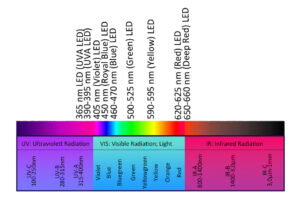

Choosing the right UV light source for a photoreactor is crucial to its performance. The type of light source used can impact both the effectiveness and the efficiency of the photochemical reactions that need to take place. Some available lamps include UV-A, B, and C lamps, and low-pressure and medium-pressure mercury lamps are also an option.

The right UV light source will depend on your applications and what reactions will be created. Therefore, speaking to an experienced professional who will help you decide what UV light source would suit your needs is paramount. It is important to consider other factors, such as the cost and efficiency of the light source, as well as its compatibility with the photoreactor.

LightSyn Illumin8 light sources

Reactor Design

There are several designs available for photoreactors that can influence their performances. The most common designs include batch reactors and continuous flow reactors, each with advantages and drawbacks.

Batch Reactors

Batch reactors are used because they are simple and easy to handle and offer precise control over reaction conditions. They are designed primarily for small-scale reactions and can only contain a set volume of reactants. Some batch reactors suffer from reduced transmittance and, therefore, longer reaction times. Additionally, scalability can be weaker than with certain other types of photoreactors.

Continuous Flow Photoreactors

Continuous flow photoreactors offer several advantages to batch UV photoreactors. A more comprehensive range of reaction conditions can be safely controlled, which is more energy-efficient and cost-effective. Continuous reactors have good scalability and are suitable for small and large-scale production.

Material Selection

The materials used in a UV photoreactor are central to its performance as they can impact its efficiency and durability. The most common materials for manufacturing photoreactors include enamelled or stainless steel, titanium, and quartz, but other materials are also an option depending on the application and reactions.

- Stainless steel is used to construct the fittings and pipes in a UV photoreactor, but the grade of steel used is crucial because it must resist chemical attacks and corrosion.

- Titanium can be a suitable material because it can enhance the effectiveness of photochemical reactions. This can be costly, however

- Quartz is commonly used because it can withstand high temperatures, is transparent to UV radiation, and does not react with most chemicals.

Control Systems

In this final section, we look at how control systems are critical features of UV photoreactors. Not only do they offer a wide range of options for controlling the parameters of an experiment, but they are also responsible for maintaining the efficiency and safety of the equipment. The control systems of a UV photoreactor can be designed to control flow rate, temperature, and UV intensity, all of which are necessary for specific experiments.

Asynt: UV Photoreactors

Asynt is a global provider of world-class equipment, services, and technologies for scientific research. Our products are specifically designed by chemists, for chemists, and respond to industry and academic demands. Among our products, we offer several safe and effective photochemical reactors for a wide range of photochemistry requirements. Their components have been carefully selected to ensure the optimal performance of each instrument.

LightSyn Lighthouse

Our LightSyn Lighthouse photoreactor is ideal for photochemists carrying out batch reactions and provides equal light exposure to the sample via our unique quartz plug-and-glow technology. The LightSyn Lighthouse offers simultaneous magnetic stirring and heating in a compact footprint and is easy to use and maintain, with built-in safety features.

LightSyn Illumin8

The LightSyn Illumin8 is a unique parallel UV photoreactor with up to 8 reactions possible simultaneously. The system features a range of UV wavelength modules that can be quickly and easily changed to suit your requirements. With 10w LED COB chips positioned close to each corresponding reaction tube, the Illumin8 efficiently delivers an even photon flux to each sample and includes a range of safety features to ensure safe operation.

PhotoFLOW

Asynt’s fReactor PhotoFLOW module was developed through a partnership between Asynt and the University of Leeds to allow scientists to quickly develop and expand their Flow Chemistry work. It can be fully customised to suit your application requirements. Additional PhotoFLOW modules can be added to each of the 5 possible CSTR (continuous supply tank reactor) positions on the fReactor platform.

To learn more about the critical features of UV photoreactors and how this impacts their performance, don’t hesitate to contact an Asynt team member today.