Evaporation is a critical process in chemistry and pharmaceutical research. In this blog we’ll discuss high-boiling solvents, and our novel tool designed to make working with them easier, the DrySyn Spiral Evaporator.

The DrySyn Spiral Evaporator allows for up to 4 parallel reactions

If you have ever worked with high-boiling solvents, you know they can provide a challenge in the lab but, with the right tools and approach, this needn’t be the case.

Let’s break down the key evaporator considerations for high-boiling solvents:

Unravelling the DrySyn Spiral Evaporator

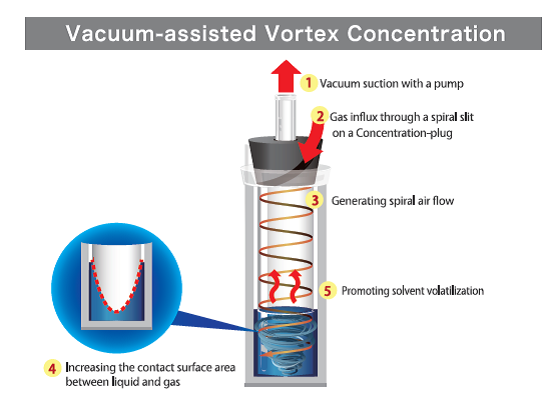

At the heart of the spiral evaporator is the innovative Biochromato Spiral Plug. The unique design creates a vortex inside your vials that turns your solvent into a thin film.

This means you get a faster vapour change with less energy consumption. Efficiency at its best.

How Does It Work?

- You connect to a vacuum source such as a suitable vacuum pump or in-house vacuum system.

- This vacuum will pull vapour out of the vials via the Spiral Plug.

- Gas flows through a spiral slit in the plug, creating a spiral motion and a thin film.

This process significantly increases the solvent’s surface area. Expanding the surface area can really help those high-boiling solvents evaporate much faster.

The Spiral increases volatility by inducing a thin film

Top Considerations for High-Boiling Solvents:

1. Temperature Control is Key

Managing temperature with high-boiling solvents is crucial. They need high levels of heat to evaporate, but too much heat can be problematic. By finding the ideal temperature, you can be effective without compromising safety or sample integrity.

2. Handling Hazardous Vapours

High-boiling solvents often mean more hazardous vapours. So, always remember to prioritise safety by wearing appropriate protective equipment and using a fume hood if necessary.

3. Safety with Volatile Chemicals

Combining volatile chemicals and heat requires a careful approach. Be sure to refer to official guidelines for the reactants you intend to work with.

4. Consider Using Inert or Dry Gas

Introducing an inert or dry gas can be a smart move for sensitive solvents. This protects your sample from unwanted reactions when it evaporates. The design of the DrySyn Spiral Evaporator accommodates reactions in an inert atmosphere with ease.

5. Choosing the Right Vials

Ensure your vials are compatible with both the high-boiling solvent and the evaporator. The DrySyn Spiral Evaporator has four different plug sizes making it compatible with various popular vial and sample sizes.

4 spiral plug sizes are available for maximum vial compatibility

Final Thoughts on Evaporation and High-Boiling Solvents

The DrySyn Spiral Evaporator, with its unique Biochromato Spiral Plug, is a standout solution for handling even high-boiling solvents. However, leveraging its full potential means paying attention to temperature management, vapour removal, lab safety, gas usage, and vial selection. By considering these factors, you can optimise your processes, ensuring efficiency and safety in your lab work.

Ready to Elevate Your Tools for High-Boiling Solvents?

We hope this overview has shed some light on spiral evaporation and its uses in the lab. If you are intrigued and eager to take your solvent evaporation to the next level, particularly with high-boiling solvents, please get in touch with our technical team who would be pleased to talk through your requirements with you via phone on +44 (0)1638 781709, via email to [email protected] or use the LIVE CHAT at the bottom right corner of your screen…

The DrySyn Spiral Evaporator is a tool designed to make your laboratory work more efficient, safer, and easier. Don’t just take our word for it. In fact, see for yourself how this technology can transform the evaporation processes you use for high-boiling solvents. Take a look at this impartial customer evaluation for and further insight into how the Spiral Evaporator can benefit your lab. You’re welcome to contact us to talk through your requirements though, of course.