A great many things around us are only here due to polymer chemistry; clothing made from synthetic fibres, polyethylene terephthalate cups, fiberglass, nylon bearings, plastic bags, polymer-based paints, epoxy glue, polyurethane foam cushion, silicone heart valves, and Teflon-coated cookware.

Until chemist Herman Staudinger developed his theories on polymers, which were thought to be a colloidal suspension of small molecule clusters without definite molecular weights held together by an unknown force, the things around us had to be manufactured primarily from naturally occurring materials. He was awarded the Nobel Prize in Chemistry in 1953 for his work.

For those in the lab today, polymer chemistry is frequently carried out under high pressure conditions as most polymerisation reactions proceed at a faster rate, and higher molecular weights are obtained, by working in this way. There is no doubt that working under high pressure conditions presents possible safety issues, however.

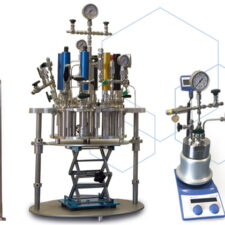

The Asynt R&D team were proud to collaborate with the University of Nottingham’s chemistry and engineering teams to develop the unique PressureSyn high pressure autoclave that utilises a unique lock and, since making it publicly available back in 2014, have received widespread positive feedback from chemists all over the world in both industry and academia.

The PressureSyn Reactor

PressureSyn Key features:

- Designed, manufactured & tested in the UK, from traceable certificated 316 stainless steel.

- Maximum working pressure of 200 bar & 200 °C

- Comes with a pressure relief valve, and a bursting disk as standard.

- Unique bracket with locking clasp so the system can be easily set up and disassembled but cannot be disassembled when under pressure.

- Pressure relieving needle-like valve with a built-in safety key that can be used to unlock the clasp only once any residual pressure is released

- Fits a specially designed DrySyn adapter base plate for use on a standard magnetic stirrer hotplate, to achieve even stirring and heating up to 200 °C.

- Agitation via magnetic stirring bar.

- Gas inlet/outlet valve with compression fitting for attaching to steel pressure tubing.

- Additional (spare) 1/8″ NPT port for customers own attachments.

- Optional spares pack which comprises 5 additional o ring seals and compression fittings.

- Optional digital thermometer and extension cable.

The PressureSyn with the clamp and unique residual pressure release / key removed

If you’d like to find out more about the PressureSyn high-pressure reactor or any of our wide range of single or multi-position pressure reactors then please let us know.

You’re welcome to send a message to our technical sales team via email at [email protected], talk with us using the live chat in the bottom right corner – or give us a call on +44 (0)1638 781 709.

| Interested in reading more? Check out our helpful blog:

Click here for 10 Simple steps for pressure reactor safety in your laboratory |

|