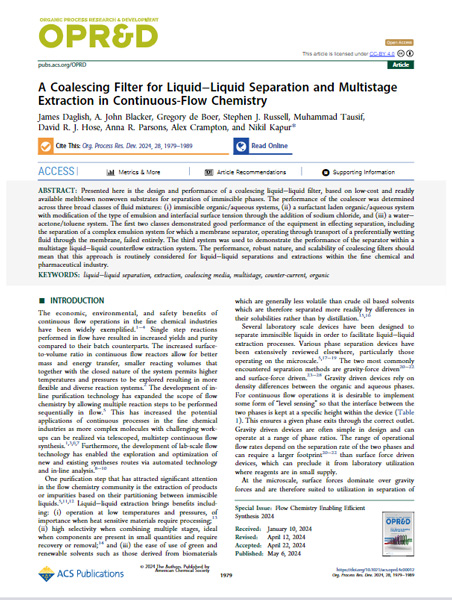

Scientists and Engineers from ,the University of Leeds and from AstraZeneca recently published a paper, titled: A Coalescing Filter for Liquid–Liquid Separation and Multistage Extraction in Continuous-Flow Chemistry that we are pleased to share with you.

The abstract reads:

Presented here is the design and performance of a coalescing liquid–liquid filter, based on low-cost and readily available meltblown nonwoven substrates for separation of immiscible phases. The performance of the coalescer was determined across three broad classes of fluid mixtures: (i) immiscible organic/aqueous systems, (ii) a surfactant laden organic/aqueous system with modification of the type of emulsion and interfacial surface tension through the addition of sodium chloride, and (iii) a water–acetone/toluene system.

Org. Process Res. Dev. 2024, 28, 5, 1979-1989

How did these perform?

The authors describe their results fully, but we have summarised with excerpts below:

The first two classes demonstrated good performance of the equipment in effecting liquid-liquid separation, including the separation of a complex emulsion system for which a membrane separator, operating through transport of a preferentially wetting fluid through the membrane, failed entirely.

The third system was used to demonstrate the performance of the separator within a multistage liquid–liquid counterflow extraction system. The performance, robust nature, and scalability of coalescing filters should mean that this approach is routinely considered for liquid–liquid separations and extractions within the fine chemical and pharmaceutical industry.

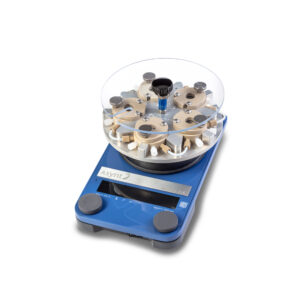

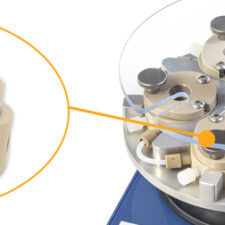

Mechanical coalescing filter design

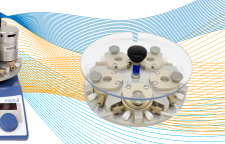

Based on the fReactor CSTR, the team designed a new mechanical coalescing filter (pictured below) which was utilised for reactions detailed within this paper.

Org. Process Res. Dev. 2024, 28, 5, 1979-1989

Media tested

- Water : toluene

- Water : ethyl acetate

- Water : dichloromethane

- Water : 1-butanol

Continuous-flow results

Generally, the coalescing filter performed excellently across all the solvent systems, with perfect separations in all except two conditions, while the membrane separator failed for one of the systems and showed crossover in two others.

The ability of the coalescing filter to separate the samples is promising, with little optimisation of the coalescing media itself which may be a fruitful area to explore.

To view the results, and read the article in full (no registration required), please click HERE.

Authors of the above-mentioned paper:

- James Daglish,

School of Mechanical Engineering, University of Leeds - A. John Blacker,

School of Chemistry, University of Leeds - Gregory de Boer,

School of Mechanical Engineering, University of Leeds - Stephen J. Russell,

School of Design, University of Leeds

- Muhammad Tausif,

School of Design, University of Leeds

- David R. J. Hose,

Chemical Development, Pharmaceutical Technology & Development, Operations, AstraZeneca

- Anna R. Parsons,

Chemical Development, Pharmaceutical Technology & Development, Operations, AstraZeneca - Alex Crampton,

Chemical Development, Pharmaceutical Technology & Development, Operations, AstraZeneca

- Nikil Kapur, (Corresponding Author)

School of Mechanical Engineering, University of Leeds

Interested in finding out more about the tools used?

Continuous-flow chemistry continues to garner interest as a sustainable and customisable way of working, with users achieving greater and purer yields. Accessible flow chemistry platforms such as the fReactor are enabling chemists at every stage of their career to utilise flow chemistry to re-evaluate earlier methods.

I hope that the paper shared here is of interest – if you’d like any further information regarding the fReactor platform used for this research, you can visit the dedicated info-site at www.fReactor.com, email our technical sales team via [email protected], use the live chat box here on our website, or call +44 (0)1638 781709 (or 502-593-0726 for USA).

We look forward to speaking with you!