The FlowSyn System - an introduction

Intuitive user-friendly flow chemistry platform

FlowSyn is a compact integrated continuous flow reactor designed for easy, safe and efficient operation.

FlowSyn is a compact integrated continuous flow reactor designed for easy, safe and efficient operation.

Two high pressure pumps deliver reagents, via a mixer, into electrically heated or cooled flow reactors. Back pressure regulators pressurise the system, allowing solvents to be superheated. Reaction outputs can be fractionated or optimised at steady state, after which the system automatically flushes itself ready for the next experiment.

Asynt offers a comprehensive range of FlowSyn models and flowpath options (PEEK, PTFE, Stainless Steel and Hastelloy®) to cater for all major flow chemistry applications.

Flow chemistry - an overview

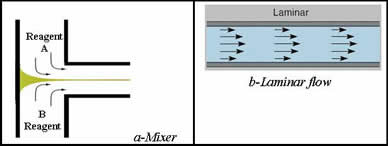

Flow chemistry is an excellent method for reaction profiling and optimisation, particularly prior to scale up. Reagents are combined in a T-shaped mixer which allows diffusion across a short distance and promotes rapid and controlled mixing. The resulting laminar flow provides for excellent reproducibility. The reactions take place in microchannels which promote excellent heat and mass transfer.

The high reproducibility of results, coupled with short processing times, allows rapid exploration of a range of reaction conditions, making flow chemistry an idea research tool.

Other benefits of flow chemistry over traditional chemistry systems include:

- Higher reaction yields

- Better selectivity

- Readily scalable

- Improved efficiency – time and materials

- Reduced handling of hazardous materials