Sub-ambient chemistry has a wide range of applications and, although less frequent than heating, represents no less a crucial area of research. Sub-ambient conditions can include anything from just below room temperature all the way down to cryogenic levels.

Why Cool Your Chemistry?

Sub-ambient chemistry makes possible research that would not otherwise be feasible at room temperature or above. Cooling a reaction can be essential for controlling reactivity, increasing selectivity, or stabilising reactive intermediates. Many highly exothermic reactions benefit from external cooling to prevent runaway conditions or thermal degradation of products. Some catalysts or reagents are only stable or active within narrow low-temperature ranges, making precise thermal management a necessity.

Datum Dual with temperature control jackets

Many notable processes require sub-ambient conditions, including nuclear magnetic resonance (NMR), the Haber process for ammonia production, distillation and condensation (in some cases), and cryogenic gas separation.

Types of Sub-Ambient Chemistry:

-

Batch – Most people are familiar with methods of cooling batch reactions, whether using an ice bath or recirculating chiller. Batch reactions require increased cooling as the size of the vessel increases.

-

Flow – Flow chemistry reactors are efficient at controlling low temperatures and exotherms due to their high surface to volume ratio which is not dependant on their volume. Another benefit of flow, when working with temperature control, is the rapid timeframe in which your reactants are cooled (or heated) as only a small volume is entering the reactor at a time.

-

Photo – Cooling can be doubly important in photochemistry, as not only is precise temperature control of the reactants needed, but also to manage the heat generated by high-energy LEDs in photoreactors.

Our Tools for Cooling Chemistry:

-

SnowStorm – Designed for single or parallel batch chemistry with vials or round-bottom flasks, with a temperature range of -30 °C to +150 °C and the potential for up to 27 reactions on a single base.

-

Cold Coil – A coil reactor wrapped around a temperature-controlled column with a range of -80 °C (depending on chiller capacity) to +150 °C. The Cold Coil can accommodate multiple coils on one base or a single coil up to 50 mL in volume.

-

ColdChip / PhotoChip – Features a temperature-controlled glass static mixer with optional LED arrays in the lid, directing light directly into the reaction for enhanced photochemistry at controlled temperatures.

-

fReactor – Our fReactor CSTR series includes the option for a cooling base, operating within a temperature range of -50 °C to +150 °C.

-

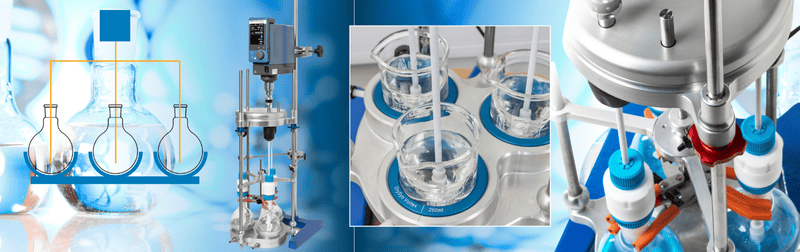

Vortex – A three-position reactor with parallel overhead stirring, ideal for screening viscous materials or those susceptible to damage from stirrer bars. Temperature range: -30 °C to +150 °C.

-

Lighthouse and Illumin8 – Single-position and parallel photoreactors, respectively. Both include LED cooling fans (and reactant cooling in the Illumin8) and are compatible with a cooling base offering a range of -30 °C to +80 °C.

-

ReactoMate – Our glass-jacketed reactor vessels offer precise temperature control using circulator fluid. For extreme temperatures, an additional vacuum jacket can be added for enhanced insulation. Operating range depends on specific configurations (volume, chiller, number of jackets, etc.).

-

FroSyn – A fluid-free cooling plate that enables rapid cooling of samples in vials or round-bottom flasks to below -60 °C.

-

Borealis – A flow photoreactor with integrated cooling for both the LED unit and the reactor coil.

-

Solstice – Designed for small-scale batch photochemical reactions in parallel, with precise temperature control. Ideal for catalyst screening, reaction optimisation, and preparing small, focused compound arrays.

-

Liquid Nitrogen Generator – In-house LN₂ generation covering outputs from 10 to 840 litres per day at 99% purity. Eliminates waste from evaporative losses during delivery and offers long-term cost and energy savings.

Conclusion:

Although heating is often the default in chemical synthesis, the importance of cooling should not be underestimated. From improving safety in exothermic reactions to enabling delicate low-temperature transformations, the ability to conduct precise sub-ambient chemistry opens new doors in both research and scale-up. Whether you’re working in batch, flow, or photochemistry, having the right cooling solution is essential.

If you’d like to know more about any of the tools mentioned in this blog don’t hesitate to get in touch via [email protected], or the live chat in the bottom righthand corner. We’ll be happy to answer any questions you have!