CondenSyn® Sustainability Report, University of Liverpool

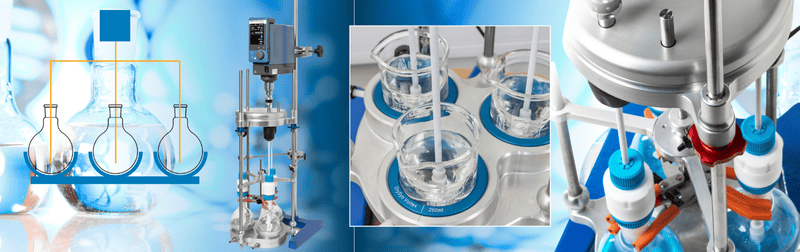

CondenSyn® Sustainability Report: The University of Liverpool tested the yields and reaction times for various experiments across the chemistry department. They used this to determine the performance of the CondenSyn,