Introduction:

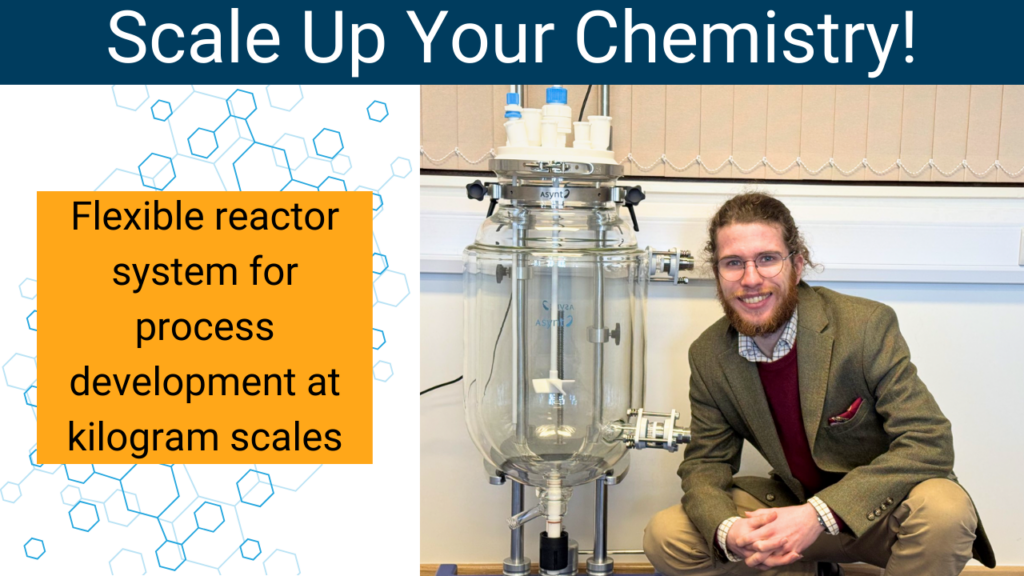

The primary purpose of a jacketed reactor system is process development and scale-up in batch chemistry. This tool can be used across a wide range of chemistry, with our own ReactoMate being used for everything from recycling coffee (more here) to API development (more here).

Despite the numerous applications of jacketed reactor systems, they all possess a few key features:

1. Height Adjustment

Being able to adjust the height of the reactor, allows you to lower the reactor for easier access to the lid ports or raise the reactor for drainage.

The Asynt Atom Jacketed Reactor System

2. Sturdy Frame

A robust and stable frame is essential for preventing vibration while the reactor is running. It also ensures that the vessel itself is secure. Asynt ReactoMate Atom’s arms, holding the vessel, are each machined from a single billet of aluminium, maintaining a high degree of stability without substantial weight (comfortably accommodating vessels 30 L and larger).

3. Jacketed Reactor (Single or Double)

The jacketed reactor allows for precise temperature regulation for scale-up reactors. We offer two overarching jacket options (although the design of each reactor can be tailored to each customer’s requirements). These options are single or double jackets.

The single jacket surrounds the vessel and is used to circulate temperature control fluid (circulators superseding hotplates and your batch scale is increased). The double jacket (commonly known as a vacuum-jacketed vessel) features a second, vacuum jacket wrapped around the first. The vacuum provides an excellent level of thermal insulation, allowing superior operation at more extreme temperatures (typically ranging from -70˚C to 150˚C).

Vacuum Jacketed Vessel

4. Lid (PTFE or Glass)

Each system’s lid can be customised to the requirements of your research with fittings of different sizes, orientations, numbers, and more. PTFE has excellent chemical resistance, while glass tends to perform better under vacuum. Glass also has the edge in chemical resistance, but PTFE is more robust and durable, and can easily be reconfigured.

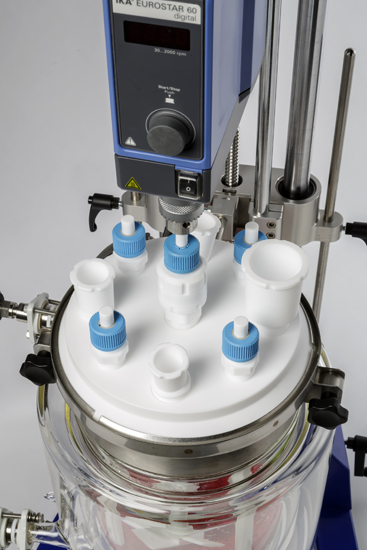

Reactor System with PTFE Lid

5. Overhead Stirrer and Chariot

Like the frame, the chariot provides a strong base for the stirrer, preventing vibration during operation. The chariot also features a highly adjustable anchor point for the stirrer, which can be positioned so that the overhead stirrer and stirrer shaft are perfectly aligned.

Conclusion:

A jacketed reactor system is an excellent tool for process development and scale-up, offering precise control and versatility across a wide range of applications. Asynt’s ReactoMate range delivers a high level of performance and reliability.

Watch full video by clicking on the thumbnail!

Explore more on how our solutions can enhance your lab’s capabilities and research below. Contact us today to learn more via the webchat in the bottom right corner or by emailing [email protected]. Alternatively, submit your details via the short form below!