A jacketed reactor vessel, used for scale up of a reaction from smaller flasks, is a glass vessel with one or more glass ‘jackets’ surrounding it. The purpose of these jackets is to provide reliable temperature regulation.

- A single jacket is used to carry temperature regulation fluid that maintains heating or cooling of the reaction.

- For improved insulation, a second jacket can be added around the first. This insulation is provided by a vacuum in the second jacket, preventing convection. Double jacketed vessels are ideal for operating at higher / lower temperatures where the ambient temperature of the room can effect temperature control/ramping.

Asynt’s jacketed vessels range from 100 mL up to 50 Litres as standard, and can be constructed in a wide range of configurations that are individually tailored to a customers’ requirements. Chemists can consider the shape of the vessel, neck size, and whether a special coating such as UV resistance is required.

- Jacketed reactor vessel

- Vacuum jacketed reactor vessel

- Amber coated for UV resistance

Uses of a jacketed vessel:

The most common use of a jacketed glass reactor is to stir a reaction under controlled temperature conditions. This is useful across a huge range of chemical processes. Asynt ReactoMate systems have been used for research into clinical haircare products, the recycling of Li-ion batteries, pharmaceutical research, synthesis scale up and much more besides.

The ReactoMate DATUM (left) and ATOM (right) accommodate a range of vessel sizes and accessories

Lids – as important as the vessel itself

When considering the design of a jacketed reactor vessel, it is essential to also map out how you intend to use your accessories. Many chemists like the flexibility of a PTFE lid as the ports can easily be removed and swapped for something different. Users should consider aspects such as the temperature probe (mentioned below), sampling/additions, and other fixtures which are to be suspended into the reaction medium and held securely. Whilst a glass lid can be custom manufactured to suit your current needs, it doesn’t offer the same level of convenience as the PTFE version, should those needs change.

PTFE jacketed lab reactor lids

Accessories:

A wide range of accessories are available for jacketed reactor vessels. These can be incorporated into the structure of the vessel itself or as additional equipment. Some examples of common accessories include:

Temperature Probe:

Our ReactoMate systems typically use a PTFE coated probe which is inserted via a port in the lid of the vessel to ensure precise temperature regulation. PTFE is highly chemically resistant so it protects the internal instrumentation.

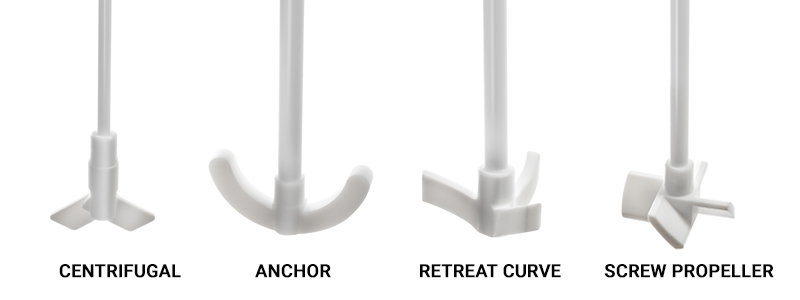

Stirrer Shaft:

The stirrer shaft is connected to an overhead stirrer that’s mounted above the vessel. This allows for a precise and consistent rate of stirring. The stirrer shaft itself can mount a variety of differently shaped heads to suite a range of fluid dynamics. You may need to also consider an alternative such as static dissipative PTFE reactor accessories. There are some examples below of different types of stirrer, however we recommend further reading in our related case study: Selecting an impeller for overhead stirring as there are a wide number of points to consider when making your selection…

Side Arm Attachments:

The vessel’s side arms are used to attach a circulator to the temperature regulating jacket and pump control fluid in and out. They are made of glass, form part of the structure of the vessel and come in a variety of fittings (for example DN15, DN25, GL18 and KF15) that can be fitted with adapters to suit more than one style of attachment .

ReactoMate side arm adapters connecting to chiller thread

Baffles:

Baffles can be built into the vessel or added with the addition of a baffle cage, often made of PTFE. The baffle cage is designed to disrupt the flow of the liquid inside the vessel as it is stirred, altering the vessels internal fluid dynamics.

Baffles can be fitted in to a vessel via a PTFE lid

Waterless Condenser:

A Condenser can also be fitted to the lid of the jacketed vessel. The CondenSyn MAXI distillation condenser, for example, can be used effectively to tap off condensed products from the reaction.

ReactoMate set up featuring CondenSyn Maxi and overhead stirrer

Conclusion:

The Asynt jacketed glass reactors are available in a wide range of configurations and sizes and cover a great variety of different applications. If you are unsure of what specification will work best for your setup and your intended chemistry, our technical support team will gladly talk things through with you to find the best solution.

So, if you’d like to know more about jacketed vessels please contact us via email to [email protected], call us on +44 (0)1638 781709 or drop us a message via the website live chat. We look forward to speaking with you…