Flow chemistry provides an excellent way to improve the efficiency and scalability of your processes. This method involves continuously pumping materials through a reactor allowing for precise temperature, pressure and residency time control.

Flow reduces the amount of waste in a process and produces high quality and precise results. If you’re just getting started in flow chemistry and want to know what kind of set up would be best for you here are some things to consider:

The Asynt fReactor is a great tool to begin flow chemistry with

The Asynt fReactor is a great tool to begin flow chemistry with

Features of a flow reactor:

In its simplest for a flow chemistry set up will include an inflow for the reactants, reactor section and outflow for the products. The inflow is normally regulated by, and pump and the reaction chamber can come in a wide variety of volumes and designs.

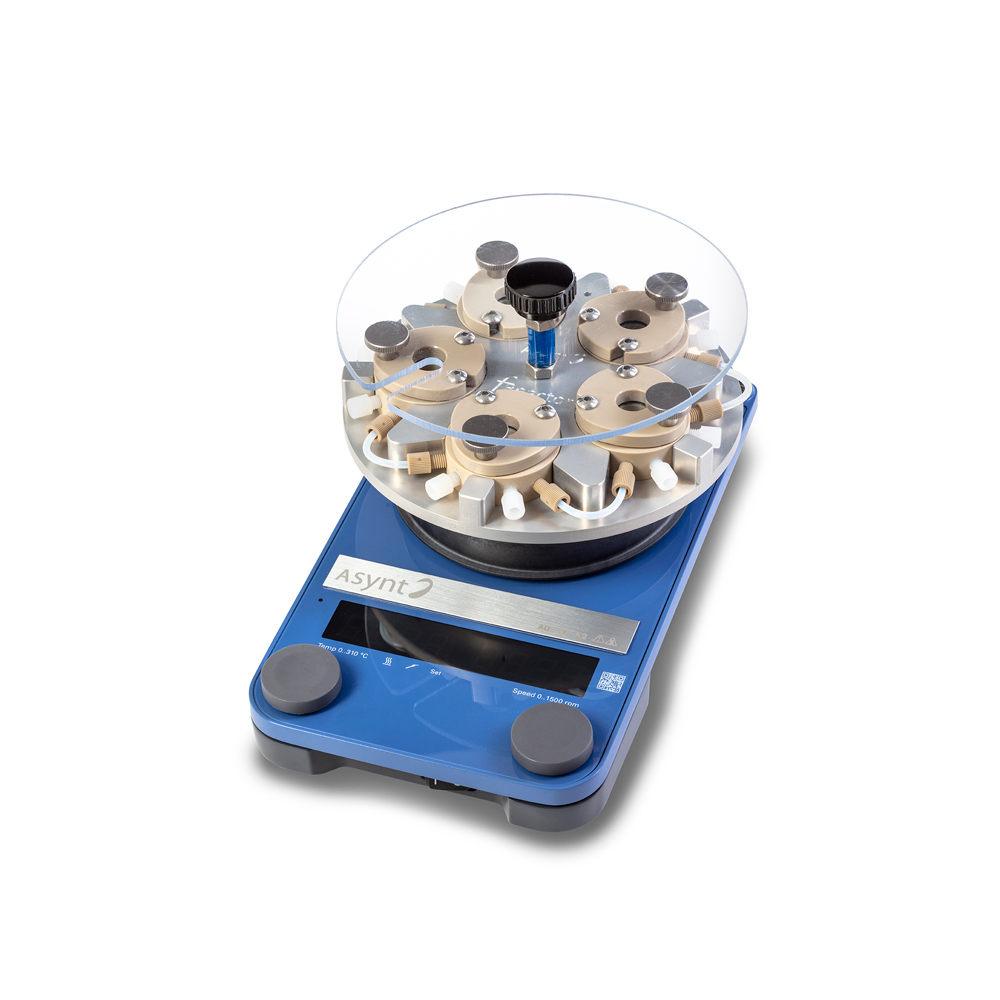

Our fReactor, designed in collaboration with the University of Leeds, features a series of 5 1.75 mL (or 7.5 mL in the case of the Maxi) CSTRs (continuous stirred tank reactor). Each of these has its own magnetic stirrer and is constructed from either PEEK or Hastelloy depending on your requirements. Tubing connects each CSTR to the next to ensure a continuous flow.

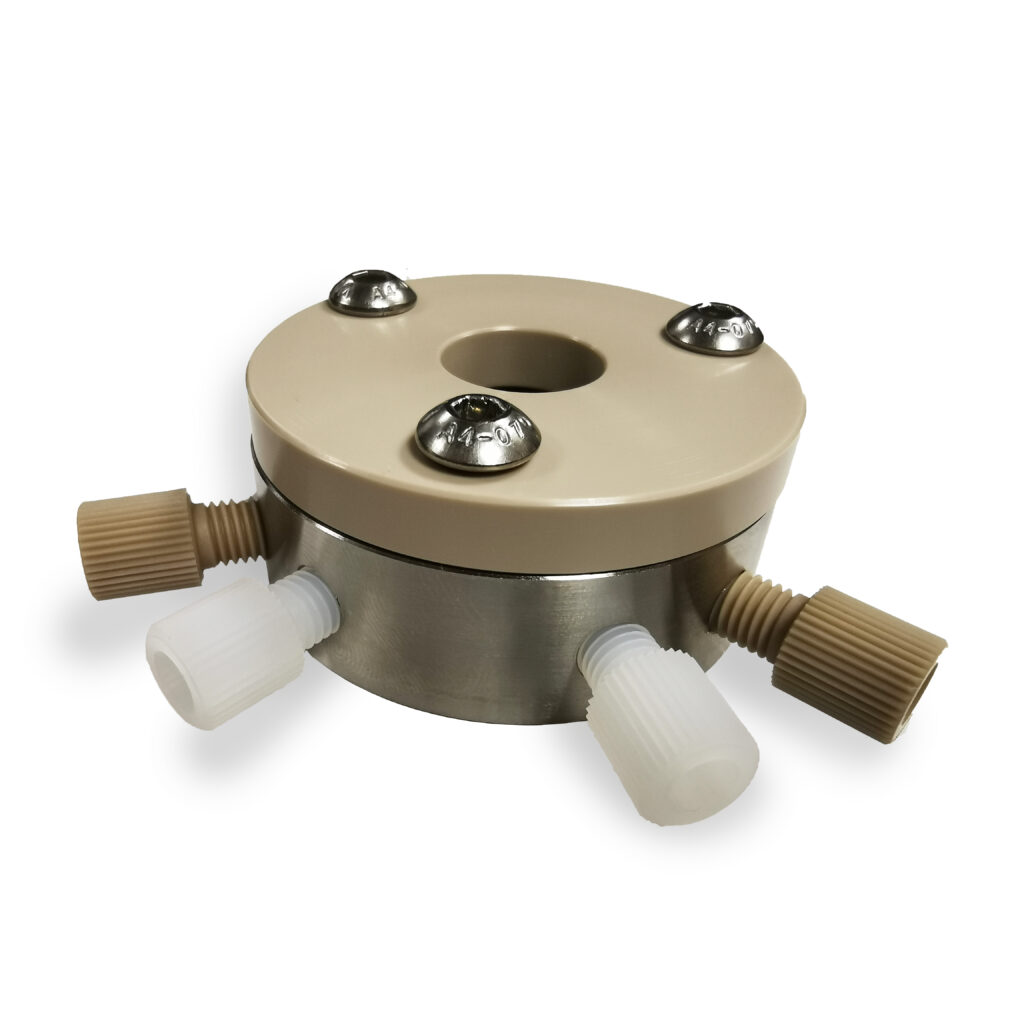

Individual CSTR with Hastelloy base

Uses of flow chemistry:

Synthesis of pharmaceuticals:

- The scalability of flow chemistry helps ensure consistent product quality as you scale up, helping ease the transition from frug discovery to manufacturing. The ability to fine tune the process also allows researchers to maximise yield and purity of their products.

Process development and optimisation:

- Flow allows for high-throughput screening of catalysts and solvents. These processes a helped especially for the ability to use automation.

Bulk chemical production:

- The increased efficiency of flow reduces operating costs by saving on raw materials and energy usage (also making for a more sustainable process). The fact that flow can easily be scaled up helps with the move from benchtop to bulk.

Emulsions and formulation:

- Precise control over the mixing of immiscible liquids allows for the creation stable emulsions and consistent droplet size / distribution. This is crucial for any process that requires consistency across large batches.

Nano-materials production:

- As with emulsions the precise control allows for the production of nanoparticles with uniform size and shape. The particles can have a wide range of uses in fields such as electronics, medicine, energy storage, and catalysis.

fReactor with hotplate for heating and magnetic stirring

fReactor with hotplate for heating and magnetic stirring

Combining flow chemistry with photochemistry:

Flow-photochemistry allows for a more uniform irradiation when compared to batch chemistry. A flow-photoreactor also provides a high level of process control and conversion making for quicker and more efficient reactions.

Our fReactor can be combined with the PhotoFLOW module in order to provide irradiation of the CSTRs. Each module contains a single LED (with a wide range of LEDs available from ultraviolet to infrared) and internal lensing to ensure that maximum power is delivered to the reaction mixture. This, along with the stirring constantly replenishing the reactants in the photo-active zone below the window, allows for fast reactions.

fReactor with 5 PhotoFLOWs in series

Conclusion:

There are a wide range of options for your first flow chemistry set up. With different volumes, temperature controls, material and accessories all available. Our fReactor is well suited to starting off with benchtop scale flow chemistry, with its wide range of options and accessories.

If you’d like to take your flow chemistry further our sister company Uniqsis have a wide range of advanced flow reactors available with excellent options for scale up, temperature and pressure control and flow-photochemistry.

If you like to know more about the fReactor, PhotoFLOW, or have any questions about flow chemistry in general, feel free to contact us via [email protected], call 01638 781709 or send us a message in the live chat at the bottom right of the website.