Combining photochemistry with flow chemistry is the natural progression from the growth of these two fields in recent years. Doing this enables safer, more efficient, and scalable processes.

Integrating these two techniques allows for excellent control over reaction parameters, opens potential new synthetic pathways and allows chemists to explore new chemical space. Several of Asynt’s products, including the fReactor PhotoFLOW, Borealis, and PhotoSyn, are designed to enable combined photochemistry and flow chemistry, and in this blog, we explore the three distinct approaches to combining these two methods as demonstrated by each.

Why Combine Photochemistry with Flow Chemistry?

Individually these two processes have significant benefits.

Photochemistry opens new reaction pathways, with photons either acting as the reagent or activating photocatalysts. This can make for more efficient, or entirely new, reactions.

Flow chemistry improves scale up and control, as well as allowing for a continuous reaction process.

When combined with a light source, flow capillaries allow for a high level of photo penetration (as shown by the below graphics), increasing the speed and efficiency of a reaction. The reaction can be scaled up with only a very minor change of diameter as a small increase in capillary diameter results in a significant increase in volume.

Another benefit of this combination is increased safety. As the process is continuous, there is only a small relative volume of reactants involved at any one time, thus reducing the risk of accident.

3 Examples for Photo / Flow Reactors

- Approach 1: Continuous Stirred Tank Reactions

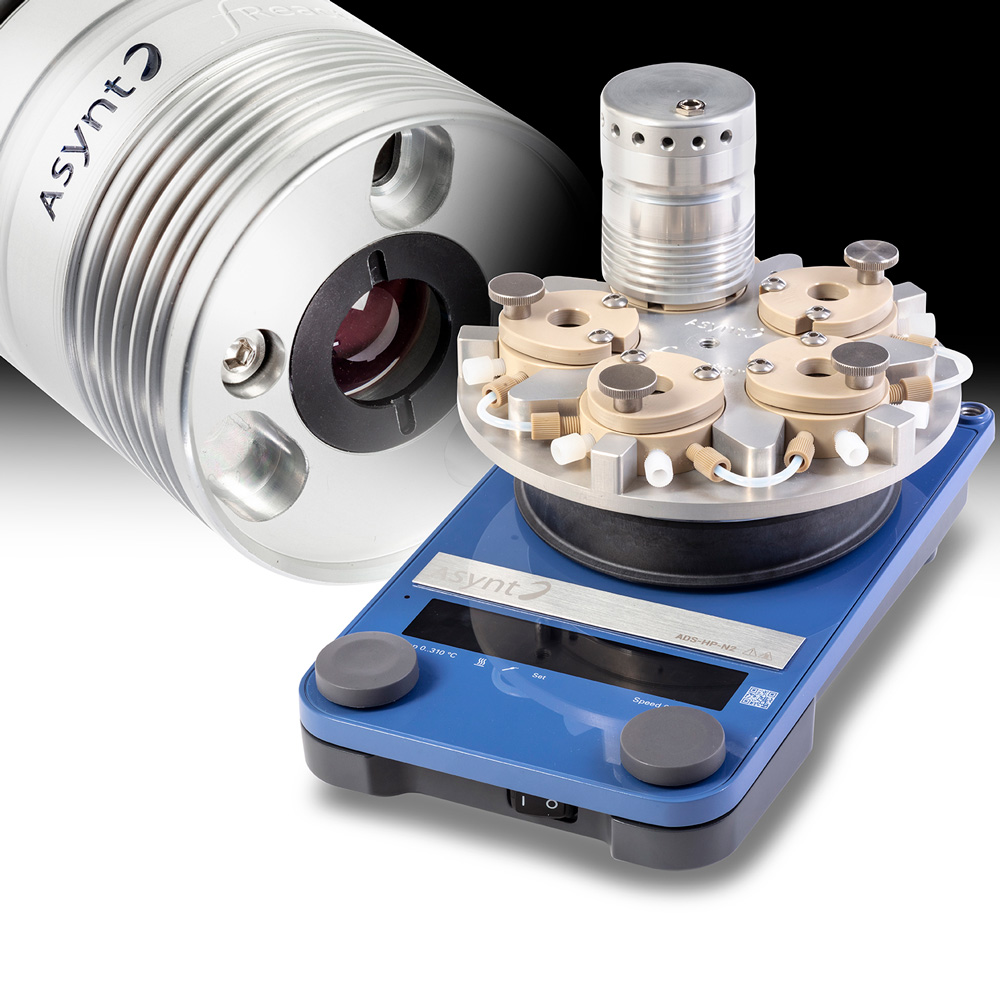

CSTRs are a common variety of flow reactor. They are ideal for reactions requiring precise control over mixing and residence time, and their scalability and efficient handling of large volumes makes them suitable for both research and industrial applications. Our fReactor sits at the low volume, research end of the spectrum and features 5 CSTRs in series (made of either PEEK or Hastelloy). It can be used as a purely flow reactor, but it also has the option of a photochemistry module in the form of the PhotoFLOW which can be used in any/all of each of the 5 CSTR positions.

The fReactor has 5 CSTRs and can accommodate 1 to 5 PhotoFLOW LED modules in a range of wavelengths from ultraviolet to red

- Approach 2: Precise Temperature and Irradiation Control

The Borealis works in tandem with the Cold Coil to provide a continuous flow and photoreactor with precise temperature regulation. It’s recommended operating temperature is between 20 ˚C and 40 ˚C but it can operate up to 150 ˚C making it a very versatile tool for photo / flow chemistry. This product features tubing wrapped in a coil (the Cold Coil) around an outward facing array of LEDs (the Borealis). This ensures uniform irradiation of the reactants as well as a consistent residence time.

Cutaway image showing the Borealis LED module within the Cold Coil

- Approach 3: High Power LED Light Source (PhotoSyn)

The PhotoSyn has a similar design to the Borealis but is significantly more powerful (180 vs 700 W). This provides an excellent based for scaling up to higher volumes. Like the Borealis, the PhotoSyn comes in a range of wavelengths from ultraviolet to visible light. This reactor has several features to help maximise efficiency such as a no-light-leak design and chromed coil reactor mandrels to maximise internal reflection.

The PhotoSyn’s LEDs have a power of up to 700 W

Conclusion:

Combining photochemistry and flow chemistry offers researchers and industrial chemists a range of benefits, from improved efficiency and scalability to enhanced safety. By combining intense, single wavelength light with a continuous flow process, it becomes possible to explore new synthetic pathways and unlock innovative chemical transformations.

Asynt’s products, including the fReactor/fReactor PhotoFLOW, Borealis, and PhotoSyn, provide distinct yet complementary approaches to combining these technologies. With CSTRs, precision of temperature and irradiation control, and high-intensity LEDs, these tools offer tailored solutions for a wide array of applications.

If you’d like to discuss how any of the solutions mentioned here would benefit your chemistry, please don’t hesitate to contact us.