As the field of photochemistry has grown in popularity, the demand for further flexibility and customisability of the equipment has also increased. There are great options available from Asynt, all of which have been designed with the user in mind, and as such are versatile and easily configured. Today we’re looking more in depth at the role of the LightSyn Lighthouse screening photoreactor and the key features that benefit the user.

1.) Wavelength

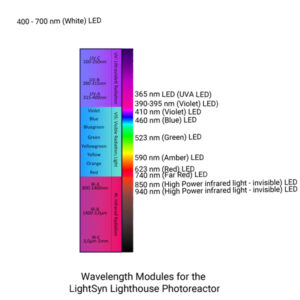

Wavelengths used in photoreactors range from ultraviolet to infrared. The LightSyn Lighthouse can be used in parallel (up to 3 reactors on just one standard laboratory hotplate) and allows for up to three simultaneous screening reactions, each with an independent, interchangeable LED Lightsource (365, 395, 410, 523, 590, 623, 740, 850 and 940 nm wavelengths are available) so screening with different wavelengths can be carried out with ease.

2.) Even Temperature Control

Temperature can also play a significant role in a photochemical reaction, so precise temperature control often plays a critical part. A cooling system can be added to a photoreactor – either to maintain an ambient temperature, or to cool the reaction below ambient (down to -30 ˚C for the LightSyn Lighthouse).

Each individual LightSyn Lighthouse photoreactor also features a built-in fan system to cool the LED chip and driver during use. Heat can also be applied to the reaction by with the use of a laboratory hotplate (or a heating/cooling circulator); The LightSyn Lighthouse is suitable for heated reactions of up to 80˚C.

3.) Stirring

For those reactions that require stirring or agitation, the LightSyn Lighthouse is designed to fit any standard magnetic stirrer. We recommend using a PTFE coated magnetic stirrer bars typically, and with each of the three reaction vessels equidistant from the centre of the magnetic field, we ensure a consistence rate and vigour of stirring for each of the LightSyn Lighthouse’s three vessels when carrying out parallel photochemical screening reactions.

PTFE coated magnetic stirrer bars are used to agitate the reaction

4.) Photon Penetration:

Most photoreactors feature an LED bulb that shines light into the reactants through air/and glass, typically reducing the intensity and efficiency of the LED source.

With Asynt’s LightSyn Lighthouse, we direct the photons from the LED directly into the reaction medium itself via a quartz rod that is submerged in the reaction medium. This process is similar in principle to a fibreoptic cable and ensures minimal loss of photons due to internal reflection.

The Lighthouse’s quartz reactor rod channels photon directly into the reaction

Conclusion:

The Asynt LightSyn Lighthouse enables users to carry out parallel photochemical reactions with ease, with options for interchangeable LED modules, heating, cooling, stirring and sampling.

If you’d like to know more, please contact our technical team who would be pleased to talk through your requirements with you via phone on +44 (0)1638 781709, via email to [email protected] or use the LIVE CHAT at the bottom right corner of your screen… We look forward to hearing from you.