Since starting Asynt way back in 2003 we have constantly strived to develop new and novel products for chemists, but what is it that drives us?

Some of our milestones are clear to regular Asynt customers…the first DrySyn launched in early in 2004 and is still a best seller! Now called the DrySyn CLASSIC it has gone through four design (performance) updates over the years, but essentially does the same; a sustainable, safe and high-performing alternative to oil baths! Listening to our customers from the outset of those first deliveries has resulted in an ever increasing ‘family’ of DrySyn blocks, with options now available for a wide range of flask and vials in single or parallel setups, and for users requiring stable lower temperatures we introduced the DrySyn SnowStorm range.

In 2007 we could see the potential for a new emerging market for Continuous Flow Chemistry tools, leading us to jointly form a new company with Grant Instruments – Uniqsis. It’s success as an independent company focused on Flow is another exciting result from us developing new and novel tools ahead of time.

Environmental issues have always been important to our customers, luckily DrySyn allows laboratories to get rid of those issues associated with an oil bath of the past! However, more recently we found more and more people asking us to help with reducing water usage in fume hoods when running reflux reactions; but how could we achieve this? From this demand, we used our expertise to develop an air cooled waterless condenser called “CondenSyn” that works brilliantly. Believe it or not the idea came from me processing a photograph of a power station in action on my laptop and using my many years of glassblowing experience!

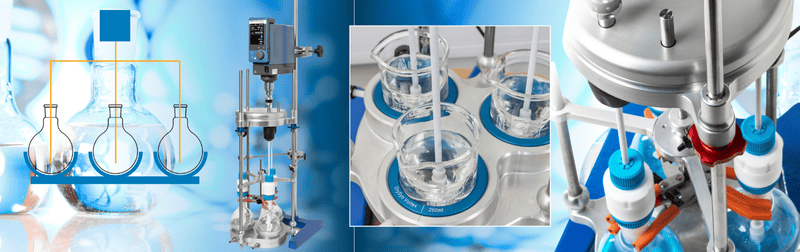

At the heart of Asynt is our motto – Collaborate, Innovate, Create and we are incredibly proud of the close collaborations we have with our customers, with our discussions often helping us to develop new product ideas. Our DrySyn OCTO parallel reactor is a great example of this, which came as the result of numerous conversations regarding the needs of a medicinal chemists at a major CRO. They needed small scale parallel reactions with heating, reflux, inert atmosphere and the ability to make samples/additions – but just couldn’t find the right piece of equipment. Asynt fully funded the development of the DrySyn OCTO to retain the IP for sales and our customer got exactly what they needed for their requirements in parallel medicinal chemistry research! Over the years we have also developed strong relationships with key Universities, helping them to commercialise ideas born in their research labs. The NEW fReactor flow chemistry platform was an idea from the iPRD at the University of Leeds, who chose Asynt as their commercial partner – something we are incredibly proud of! The fReactor is a simple Continuous flow Stirred Tank Reactor (CSTR) that works with any standard magnetic hotplate stirrer and allows the user to venture into flow chemistry without any previous expertise or expensive equipment. Here at Asynt our role was to initially develop the production units and then commercialise these for worldwide sales. They are proving very successful and this year will see and expansion to the range with many additions for fReactor in the pipeline; including for use with gas and photochemical reactions!

Speaking of photochemistry, our sister company Uniqsis already has it’s own high power continuous flow module, the PhotoSyn, and this year at Asynt we will also be launching our first photochemistry reactor for parallel synthesis…so watch this space!!