Transforming societies to believe in a sustainable future is a significant challenge in every laboratory. Here at Asynt we have made it their mission to provide green, energy efficient and cost-effective solutions to the purchasing of lab equipment worldwide.

In order to look at alternative greener solutions, to already popular laboratory equipment, we’ve put this brief summary together to help your lab reduce its carbon footprint, save energy and reduce water consumption.

CondenSyn

Our lightweight, water-free, air condenser is not only more environmentally friendly than conventional water condensers, it also prevents unnecessary flooding! CondenSyn’s unique design is protected by European Community Registered Designs and is helping transform synthesis laboratories worldwide.

Did you know a water condenser wastes three litres of water every minute? Saving water and preventing floods is paramount in laboratories. Make the switch.

Chiller Systems

Asynt offers a wide selection of recirculating chillers from both Huber and Julabo. One typical rotary evaporator will use approximately seven litres of good quality tap water every minute, switching to a chiller can save this! Both Huber and Julabo are pioneers when it comes to environmentally friendly recirculating chillers, helping to conserve that precious tap water! Did we mention that by making the switch you could save over £2600 per year, per rotary evaporator, in water costs!

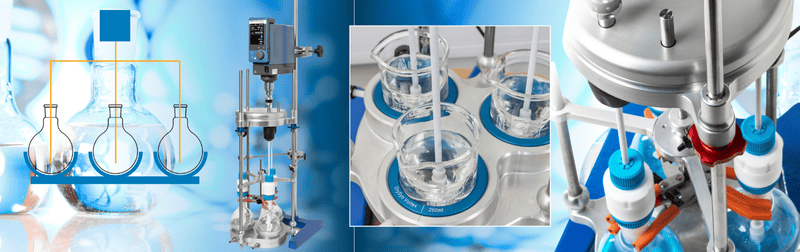

DrySyn

Oil baths are one of the main causes of fire in the laboratory and our range of DrySyn heating blocks are a superb alternative for heating reactions in vials, tubes and round-bottom flasks. Not only do you save money on the purchasing of expensive oils, but it also removes the need for oil disposal, reduces your carbon footprint and eliminates the production of harmful, potentially carcinogenic, fumes.

The DrySyn range also enables you to perform more than one reaction on a stirrer hotplate, increasing productivity, reducing energy consumption and providing a greener alternative to multiple hotplate reactions. Not to mention freeing up precious fume hood space!

Using the DrySyn and Condensyn, in place of traditional oil baths and water-cooled condensers, offers significant savings in laboratory running costs. Furthermore, a reduction in oil spillages prevents safety hazard threats which cost time and materials to decontaminate.

Vacuubrand Diaphragm Pumps

Vacuum pumps from Vacuubrand can help reduce carbon footprints, energy levels and make laboratories more sustainable too. By switching to a diaphragm pump you can eliminate the oil usage associated with rotary vane pumps, whilst the addition of a CondenSyn to the pump exhaust can trap any escaping vapours. VARIO control technology optimizes pumping speed automatically, helping processes to run faster and consumer less energy.

E3 Energy Efficient Drying Ovens

The E3 range of glassware drying cabinets are energy efficient, eco-friendly, safe and economic to run – providing a novel and sustainable solution to the drying of laboratory glassware. Now with a touch screen system, the E3 range offers intuitive control and reproducible environments, with firmware for energy saving including an adjustable automatic on/off timer.

Liquid Nitrogen Generators

In the past, Liquid Nitrogen was only ever available on site via road tanker delivery – which posed many problems, not least the inevitable delay that comes with traffic and the wastage from boil-off! Liquid Nitrogen generators now offer a greener, cleaner, alternative, with reduced carbon footprints and CO2 emissions, all available on demand at the push of a button!

The team at Asynt understand how, by being innovative and producing laboratory products that make working conditions safer, greener and more sustainable, we can make small steps in helping to reduce the carbon footprint and improve current laboratory methods. After all, saving the planet doesn’t have to cost the Earth.

For further information on how to make your laboratories more sustainable please contact [email protected] or call the office on +44 (0)1638 781 709.