A high pressure reactor for the laboratory can come in a wide variety of configurations and can be utilised in an equally diverse range of chemistry fields. When deciding which reactor design will be best suited to your own processes, there are several key features to consider which we detail below.

Material and Capabilities:

High pressure reactor vessels can be machined from a selection of metals. The most common being 316 stainless steel, Hastelloy and Inconel although alternatives are available.

- 316 Stainless steel represents the mainstay of our pressure reactors. It has a decent level of chemical resistance (which can be further improved by the addition of a glass or PTFE liner) and high temperature tolerance while also being less expensive than Hastelloy and Inconel.

- Hastelloy is an alloy primarily consisting of nickel and molybdenum. It has a very high resistance to corrosion and fatigue, while also having a higher maximum operating temperature than stainless steel. This makes it ideal for operating under more extreme conditions, but it does come at with a higher price tag.

- Inconel is the most resistant, and most expensive, of the three and is an alloy primarily comprised of nickel and chromium. It can provide excellent performance across the board. In fact, Inconel is so durable it was used in the thrust chamber of the Saturn V F-1 rocket engines!

Accessories and safety features:

The first key accessory are the aforementioned vessel liners. These are designed to fit flush within the pressure vessels chamber and add an extra level of protection from corrosion and make cleaning easier. These are usually made from glass or PTFE depending upon your requirements.

Sampling and adding to reactions whilst maintaining high pressure conditions can be a key factor in many chemistry procedures, and Asynt’s lab reactors can be configured to allow for these to be performed safely while operating under high temperature and pressure.

Safety features include relief valves and bursting disks, calibrated to vent/rupture before surpassing the vessel’s design pressure. This ensures that any pressure is released before risking damage to the vessel – or the human operating the reactor…

Another safety feature is the unique clamp-key locking system for the PressureSyn single-position reactors. These reactors feature a novel clamp that can only be unlocked with a key which is inserted in to the residual pressure release valve, forming a tight seal. This way the clamp can only be removed, and the vessel opened, once the internal pressure has returned to ambient by removing the key.

|

|

| PressureSyn: designed in conjunction with the University of Nottingham. This features the novel locking mechanism which prevents opening whilst any residual pressure remains. | The unique neck clamp has been removed from the vessel here. The object in front is both the key to unlock this clamp and the residual pressure release tool. |

Single or multiple position?

Single Pressure reactors are fairly self-explanatory. They are highly customisable in terms of operating pressure, temperature, volume and accessories (along with useful standard options). Single position pressure reactors can be configured to operate at generally more extreme conditions than their parallel counterparts.

Parallel pressure reactors enable multiple reactions to be carried out simultaneously. Parallel reactors can either operate multiple chambers running at the same conditions (pressure / temperature etc.) or these can be individually controlled, with different conditions for each cell. Our technical team can talk your requirements through with you and advise on the most appropriate solution.

Our Multicell parallel pressure reactor allows for up to 10 simultaneous reactions

Uses:

- Hydrogenation – hydrogen is added to unsaturated compounds under precise temperature and pressure.

- Polymerisation – the extreme conditions within the pressure reactor allow for the development of polymers that can’t be synthesised under ambient conditions.

- Carbonylation – CO can be precisely and safely added to the reaction.

- Homogenous and heterogenous catalysis – once again the precise conditions can be optimised for the catalysts being used.

- Parallel synthesis – this is enabled by our highly flexible and customisable multi-position reactors.

- Super critical studies – pressure reactors allow for the testing of fluids beyond their critical limits, for example studying their unique solvent properties.

- Corrosion testing – materials can be tested for their resistance to chemical degradation under extreme conditions.

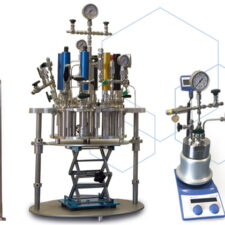

A selection of our previous custom pressure reactors. We can provide a wide range of material, volumes, capabilities and accessories to suit your lab

Conclusion:

We’ve detailed the key features and options to consider when looking for an appropriate high pressure reactor, including scale, temperature range, chemical resistance, and safety features. Users should carefully consider the parameters of their intended work to ensure suitability of the apparatus.

Asynt are proud to offer a wide array of standardised high pressure reactor specifications which are ideal for a variety of reactions, however all of these can be tailored to meet your specific requirements.

Why not have a talk with us today and see how we can take the pressure off and help you achieve the best possible results?

Contact us at [email protected], call 01638 781709 or drop us a message in the website’s chat.