Jacketed reactors provide an excellent means of achieving reliable and consistent results, allowing scientists to scale up their reactions and increase yield from the process materials being utilized.

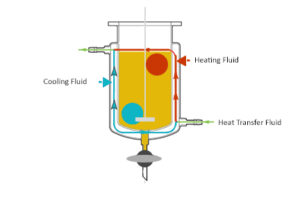

Every good chemist knows the importance of accurate temperature management to a controlled reaction. It underlies critical safety and quality parameters and may ultimately mean the difference between the success or failure of the reaction. Reaction vessels typically use cooling and/or heating jackets to achieve optimal temperature control: removing heat in exothermic reactions and increasing heat in endothermic reactions.

In this article, we discuss some of the applications of jacketed reactors and how to get the best out of your system.

Jacketed Reactors are Revolutionary Pieces of Equipment

Reactors (reaction vessels) are containers in which chemical reactions are carried out. Given the variety of types of reactions carried out in chemical processing, reactors are made in a huge range of configurations, from a variety of materials. They have a plethora of uses in the chemical industry such as distillation, API manufacture, crystallization, extraction, and post-processing to name only a few. Manufactured in a range of formats, sizes, and materials (typically glass or stainless steel) to suit the end-user’s chemistry, there are almost limitless options for customization.

So, what is a jacket in the context of reaction vessels?

Temperature control jackets come in both single and double configurations (jacketed or vacuum jacketed). Single jacket systems use a chiller to circulate liquid all around the reactor whereas double jacket systems use the chiller to circulate the liquid through the inner jacket. The outer jacket serves as vacuum insulation, ensuring that the vessel stays at the desired temperature – and preventing condensation/ice formation at ultra-low temperatures.

Key Uses of Jacketed Reactors

Jacketed reactors enhance temperature control which in turn leads to enhanced product quality. They are used in a diverse range of applications from pharmaceuticals to engine oil. They control the heat of exothermic reactions or decrease the viscosity of highly viscous liquids.

Your reaction quality can be affected by the type of agitation used, the size and shape of the reactor, and the addition of baffles as all these conditions affect mixing capabilities. You should also consider other conditions which can affect your reaction such as photosensitivity for example – amber coating your jacketed reactor vessel may be required.

Many jacketed reactors can be connected to laboratory automation software, offering the user precise control over the temperature and process of the reactor, providing computerized data and reporting.

Stainless Steel vs. Glass

There are positives and negatives to using both steel and glass for jacketed reactors. Ultimately, you must decide what you require the vessel for. Stainless steel (or you may require alloys such as Hastelloy for increased chemical resistance) is generally utilized when using above reflux, and when pressurized conditions are required however this type of reactor is usually more expensive than a glass reactor and there is no reaction visibility possible.

Jacketed Reactors from Asynt

Asynt offer a range of jacketed reactors for chemical processes up to 100L. All reactors supplied are available with a range of customization options to suit your exact requirements and are manufactured to your chosen specification. Choose from standard jacketed reactor specifications or fully bespoke. To find out more about the jacketed reactors we offer, visit our dedicated webpage.