Rotary evaporators (rotovaps) are devices employed for removing solvents efficiently via the process of evaporation. The rotary evaporation process is one of the most widely used methods of solvent evaporation due to its optimal extraction and distillation performance.

Rotary evaporators are also used for concentration, crystallization, drying, separation, and solvent recovery in addition to the continuous distillation of volatile solvents and are utilized in various fields and applications, including pharmaceutical, chemical, and biotechnology industries.

How Does a Rotary Evaporator Work?

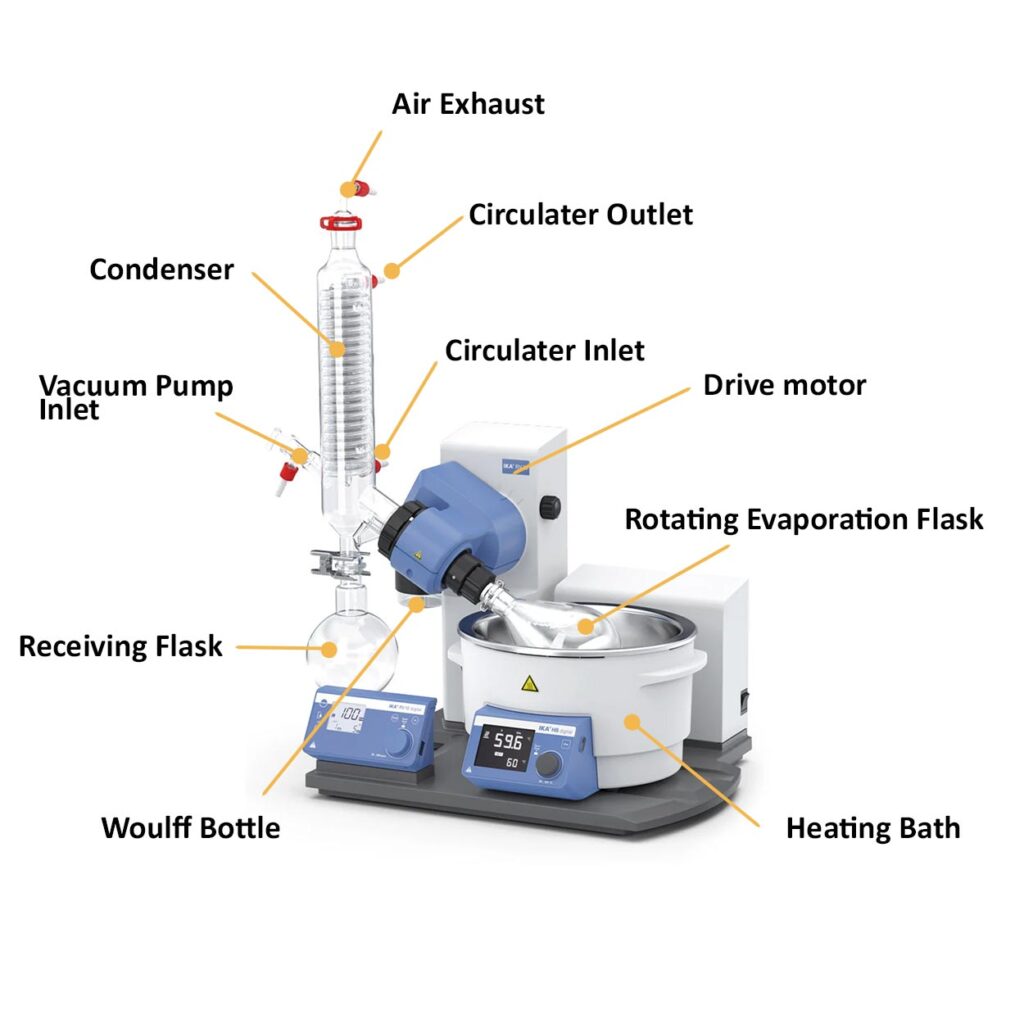

Rotary evaporators work on the principle that solvents have a range of boiling points, which decrease under reduced pressure. The evaporation flask rotates at a specified speed forcing the materials to form a large area of thin film on the inner wall of the flask.

The flask is heated evenly, and materials with a lower boiling point rapidly evaporate. Recycling of the solvent stream occurs in the receiving flask, following cooling by the glass condenser.

Key Benefits of Using a Rotary Evaporator

Users can carry out solvent removal faster and more efficiently than evaporation under atmospheric pressure, thus saving time and increasing productivity in the laboratory. In part, this accelerated evaporation is due to the film’s formation on the flask’s inner surface, which increases evaporation significantly. It is therefor relatively quick to achieve solvent removal (depending on volume and solvent). Rotary evaporators are simple to use and are commonly found in laboratories.

What Factors are Important When Selecting a Rotary Evaporator?

One of the most critical considerations for rotary evaporator selection is solvent type. Understanding the properties of solvent is beneficial as it informs the user about the total vacuum required.

Solvent boiling points decrease substantially when under vacuum, for example:

| Solvent | Boiling Point at 1 mbar | Boiling Point at 53 mbar |

| Acetonitrile | 81°C | 7.7°C |

| Ethanol | 78.4°C | 19°C |

Monitoring low boiling points is essential so that the bath temperature does not exceed these temperatures.

It is vital to consider heating and cooling capacity. The temperature difference between the solvent solution and the condenser must be sufficient. Typically, the condenser is cooled using dry ice or circulated tap water, but recirculated chillers can be used and are beneficial because they are less labour-intensive to use. Circulators are greener, save water, and, over a period of time, more cost-effective. They also prevent potential laboratory floods.

Tailoring automation and accessories can ensure streamlined workflow when using rotary evaporators. Certain automated features such as motorized lifts and automatic boiling point detection can minimize operational time.

Which Rotary Evaporator is Right for You?

Asynt supplies a range of rotary evaporators to suit every application need. Our portfolio contains many different sizes and configurations. We also offer a range of accessories to customize the instrument.

Employing benchtop rotary evaporators is an ideal solution for labs that are low on space and require an instrument with a small footprint. The design of these instruments accommodates evaporation of 5 litres or less. Lifting arms and digital controls allow for automation.

Inversely, we offer scale-up rotary evaporators. These can facilitate 50-100L of evaporation. These rotary evaporators are suitable for larger-scale applications and can be paired with a range of chillers and automation features.

If you would like to find out more about choosing a suitable rotary evaporator for your application, get in touch with the team of experts at Asynt today.

|

|

Sustainable and practical

Find out how much water, and cash, you could be saving with the right chiller paired with your rotary evaporator. Download the flyer in PDF format HERE.