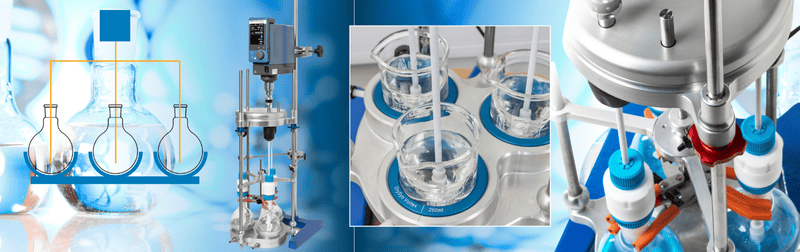

Asynt has developed a novel high-pressure reactor array that integrates directly with a range of 10 position reaction stations, enabling scientists to undertake 10 independently pressurised reactions (up to 100 barg) in parallel.

These reaction systems are designed to carry out up to ten individual reactions, each with independent temperature control between -30 °C and +150 °C, making it perfect for Design of Experiments (DoE) testing. In chemical development, DoE protocols have become a reference method to speed up reaction optimization, since it allows the assessment of a large number of reaction parameters through a small number of experiments.

Integration of the new high-pressure reactor array module enables scientists to run a mix of reactions simultaneously, with each experiment receiving different conditions. This extends the utility of the users reaction station, maximising efficiency and saving precious fume hood space. Manufactured as standard from durable 316 Stainless Steel – Asynt is also able to fabricate the system from exotic alloys such as Hastelloy or Inconel.

For more information go to our product page here: Parallel Pressure Reactor Modules

Or contact us to discuss your requirements.

Download the full press release here: asyntpr100 – New System for High Pressure Reaction Screening

Nouveau système de contrôle des réactions à haute pression

Neues System für Hochdruck-Reaktionsscreening

Nuevo sistema para para la filtración de reacciones a alta presión