Asynt reports on its collaboration with the Department of Chemistry, University of Bath (UK) in the development of a novel mesoscale segmented flow reactor.

In an ideal flow crystallizer, nucleation and growth occur at the same location and rate for a given set of parameters. Particles are well suspended with good mixing throughout the reactor, while plug flow is achieved. However until recently traditional flow crystallizers have been either designed for large volumes or for very small volumes in microreactors with a narrow internal diameter, which makes them incompatible with any solids above the nanometre scale. To enable small scale production of micrometre to centimetre sized crystals without the need for kilograms of starting material the University of Bath has developed, in cooperation with Asynt, a new liquid segmented mesoscale tubular reactor, which has been proven able to run for 5 hours without fouling issues and with instant recovery of solids.

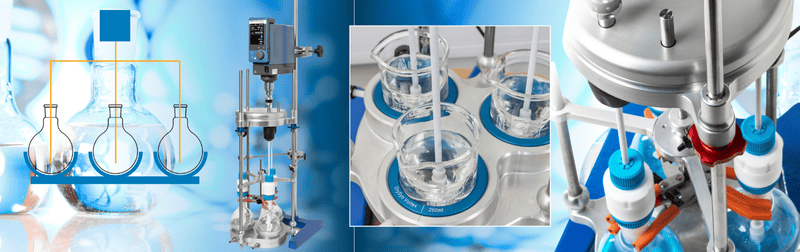

Dr Arran Solomonsz, Technical Manager at Asynt commented “We were delighted to be chosen by the University of Bath as a collaborative partner in the development of their mesoscale segmented flow reactor and the results of the initial evaluation experiments carried out on the system look very exciting”. He added “As well as designing the mesoscale reactor framework exterior, Asynt were involved in the design and supply of robust, high performance heating technology for feed vessels, custom manufactured meso coil reactor heaters, detailed specification of the required pumps as well as flexible tubing jackets to maintain the temperature within these conduits”.

Dr Karen Robertson of the University of Bath said “We chose to work with Asynt because of their extensive experience of designing specialist reactor systems and expertise in heating block technology. Throughout the development and experimental trials we have been very happy with the technical knowledge, design ideas and overall support provided by Asynt”.

The University of Bath mesoscale flow reactor has been demonstrated to be capable of processing precipitation reactions and crystallizations. The modular nature of the system, range of configurations possible and independent control over feed solutions results in a highly versatile platform. A wide range of crystallizations or reactions can be performed using this apparatus with a high degree of kinetic control. The use of liquid-segmented flow in the system enables plug flow to be generated and mitigates encrustation while providing a sterile environment in which primary nucleation can occur free of external stimulus. As a result nucleation is induced in a consistent and reproducible manner, a critical advantage in delivering selectivity and consistency in the solid form particles produced. The design of the system which provides separation of the carrier fluid prior to filtration, without impact on the precipitate, enables continuous use of this crystallizer. The small scale of the system makes it ideal for research laboratories and the production of high value and rare chemicals.

For further information please visit http://pubs.acs.org/doi/abs/10.1021/acs.cgd.6b00885 or contact [email protected] or Asynt on +44-1638-781709 / [email protected].

The University of Bath (www.bath.ac.uk) is part of the EPSRC Centre for Innovative Manufacturing in Continuous Manufacturing and Crystallisation (CMAC), whose vision is to accelerate the adoption of continuous manufacturing and crystallisation processes, systems and plants for the production of high-value chemical products; improving their quality at lower costs, more quickly and sustainably. The aim is to create an effective partnership with industry, academia and public bodies.

To download the press release in PDF format click HERE.