FlowLab Flow Chemistry system

FlowLab is a versatile modular flow chemistry system built around the same high quality components as those used in theFlowSyn, but with the automated valves omitted to contain costs.

The system utilises individual reactor modules for maximum choice and flexibility. Dependent on the temperature range required; choose from 3 standard configurations:

- FlowLab includes a Uniqsis HotCoil heated reactor station and enables reaction temperatures from ambient to 300 oC.

- FlowLab Cold includes the Polar Bear Plus Flow and operates in the range -40 oC to 150 oC; without the need for card-ice or liquid nitrogen.

- FlowLab Column is designed for heterogeneous catalytic flow chemistry applications. It has a high pressure 316L SS flow path and includes a HotColumn adaptor fitted with a stainless steel HPLC column reactor in an insulated holder.

The standard system comes complete with 2 high pressure pumps and dedicated FlowLab control software that enables full manual control and the ability to program a single automated experiment.

The reactor modules are compatible with all Asynt and Uniqsis coil reactors. Column reactors can also be fitted by adding the HotColumn accessory and our glass Static reactor/mixer Chips can be mounted on the Polar Bear Plus Flow by specifying the additional Chip Holder.

The system can easily be upgraded because the FlowLab software auto-detects and can control up to 3 pumps and 2 reactor modules, making it particularly versatile.

- Reactor options include HotCoil, HotColumn, Polar Bear Plus

- -40 oC to +300 oC temperature range options;

- Pmax = 100 bar

- User-friendly control interface for walk-up use

- Stainless steel or glass column reactors

- Future proof – can be upgraded to include 3 HPLC pumps & 2 reactor modules

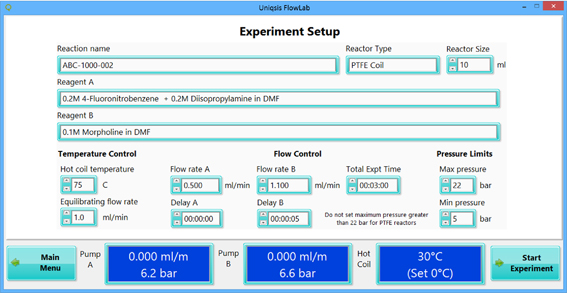

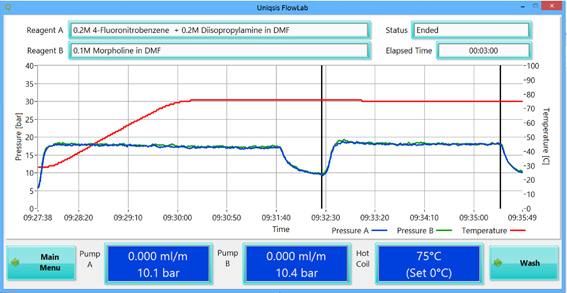

The FlowLab application affords control of the system via a step-through interface that is straightforward to use. Specific control screens allow users to modify system settings and perform automated priming and wash functions in addition to designing new, or loading previous, experiments. Reactions can be run automatically on a time basis, and reaction progress is monitored in real-time from a plot of temperature and pressures. The reagents used can be entered in text fields and logged data is automatically saved.

For operational safety, FlowLab software monitors pressure and temperature and will automatically shut down if there is a blockage, leakage or overheating.

All system components are CE marked and are covered by a 12 month warranty against component malfunction and workmanship.

UK / Europe / Global Delivery

Developed in collaboration with our clients / Bespoke design service

Committed to developing sustainable & practical improvements for scientists worldwide

Martyn Fordham, MD